Indoor full-color LED displays are basically not waterproof. However, the installation of indoor full-color LED screens must also consider these issues.

Today, follow LEGIDATECH to learn about Indoor full-color LED Screen Installation Guide.

It is strictly forbidden to leak water or under the air conditioner in the LED display installation area to prevent water leakage from damaging the LED screen.

The installation environment humidity must be lower than 70% (condensation state).

There should be no excessive dust operations at the installation site, such as welding, cutting steel structures, house painting, etc.

(dust can easily generate static electricity, and metal shavings can short-circuit the circuit and cause damage to the screen).

Pay attention to the following points when handling, transferring, and storing products in the packaged state.

Keep the module away from direct sunlight and place it upward.

Handle it with care when transporting to avoid stepping on the product.

In order to ensure the normal operation and service life of LEDs, a certain temperature and humidity must be maintained in the computer room.

The working environment temperature is -10~45℃. If the temperature does not meet the standard, it may cause equipment failure.

If the temperature exceeds the standard, the equipment may burn out.

The relative humidity is 8%~85%. If the humidity in the computer room is too high for a long time, it may easily cause poor insulation of the insulation material or even leakage.

Sometimes it is also prone to changes in the mechanical properties of materials and corrosion of metal parts;

If the relative humidity is too low, the insulating gasket will shrink and cause the fastening screws to loosen.

At the same time, in dry climate environments, static electricity is easily generated, which can harm the circuits on the switch;

Excessive temperature will be more harmful. Long-term high temperature will accelerate the aging process of insulation materials.

The reliability of the LED is greatly reduced and its lifespan is seriously affected.

Preparation before installing indoor full-color LED Screen

1. Prepare the corresponding tools before installatilling indoor full-color LED Screen : electrostatic rings, electrostatic gloves, etc. During the operation, you must wear electrostatic rings and electrostatic gloves.

2. Check the appearance of the box and carton packaging. If there is any damage, take photos to record and check the damage before unpacking.

3. Remove the carton packing tape, take out the unit cabinet from the packaging carton, place it on a protected platform with the light side facing up, and then remove the Styrofoam, anti-static bag, and blister protective cover in sequence.

4. Check whether the outer surface of the box is scratched, whether the LED is knocked off, whether the screws are loose, etc.

Others are marked and placed in designated areas to await repairs. Take serious photos to record and query the bad phenomenon.

5. Perform lighting inspection on each box separately. This process must be handled with care and ensure that each Indoor LED display must be in a qualified state when the screen is assembled.

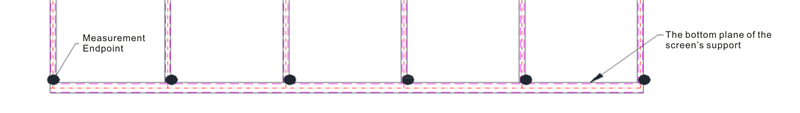

Levelness of the bottom of the indoor full-color LED Screen steel structure support

Ensure that the plane on which the bottom indoor full-color LED Screen is placed is on the same level.

Method:

Select several points on the bottom plane and use a spirit level to measure horizontally to see if it meets the standards. (Guarantee that the flatness within a horizontal length of 7m is within ±1mm)

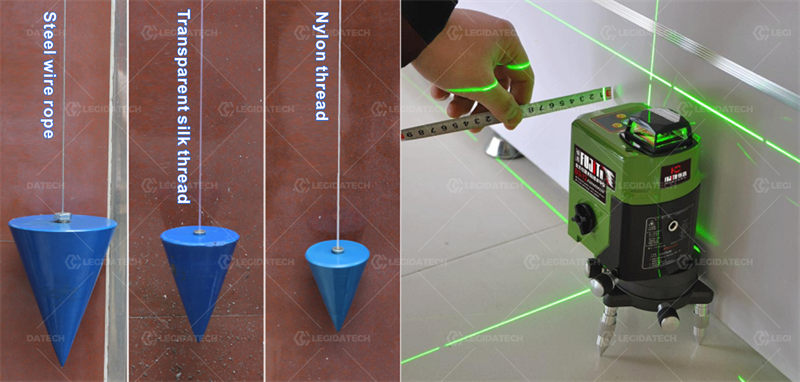

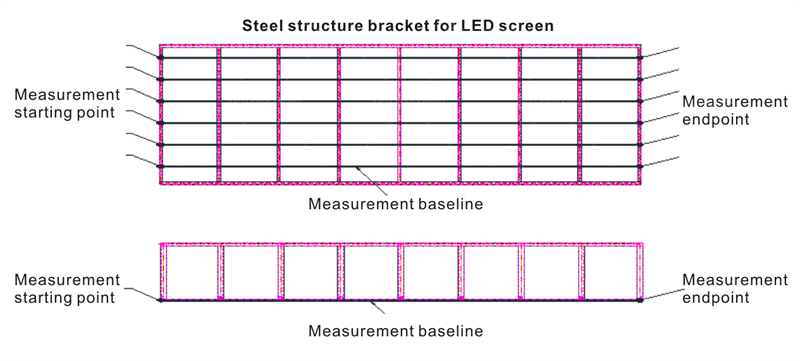

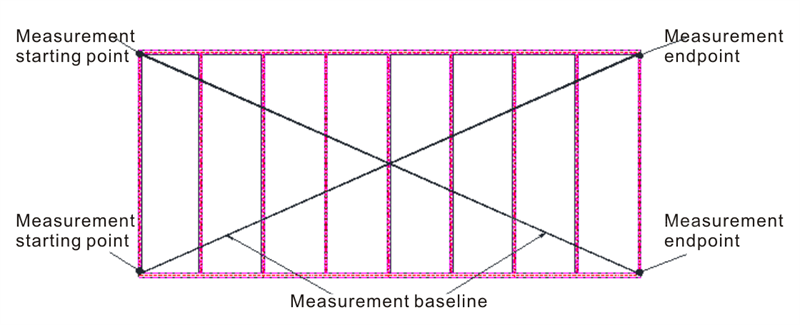

Measurement of vertical and horizontal angles of indoor full-color screen brackets

Measure the verticality of each column of the bracket, especially the columns on the sides, to ensure that the bracket is in a square and non-deformed state.

Method 1:

Hang a plumb bob with a nylon rope and hang it from the top of the shelf to see if the distance between the rope and the vertical steel is consistent. If they are consistent, they are vertical, if not, they are not vertical.

Method 2:

Use a laser level to measure.

Measurement of the front end flatness of the stand of the indoor full-color LED display

Make sure that all square steel surfaces at the front end of the bracket are on the same indoor full-color LED display. Measurement

method: Use a laser level to select different points on the front plane for comparison and measurement to see if they meet the specified standards.

Indoor full color LED display of a single cabinet qualified test

In order to prevent the cabinet from being damaged due to collision, friction and other adverse factors during transportation.

Or if the power cord or signal cable is loose, a testing system must be used to conduct a qualification test on each cabinet before it is put on the shelf.

Ensure that each cabinet has no out-of-control modules, no out-of-control points, and normal scanning, etc.

If there are any problems, all problems must be dealt with before being put on the shelf for installation, so as to reduce the defective rate after being put on the shelf and speed up the debugging progress in the future.

Indoor LED Screen assembly

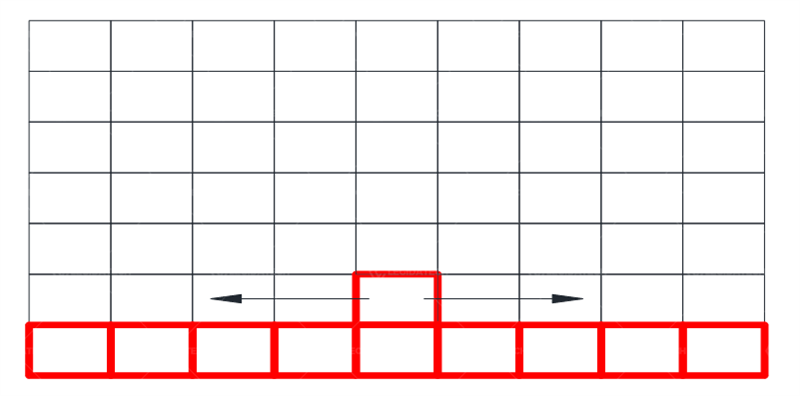

After the installation of the first layer of cabinets is completed and the measurements are correct, the middle layer of cabinets can be installed.

Choose the middle panel of the second layer and install it dispersedly on both sides (the purpose of this installation is to spread the tolerance from the middle to both sides, ultimately reducing the tolerance)

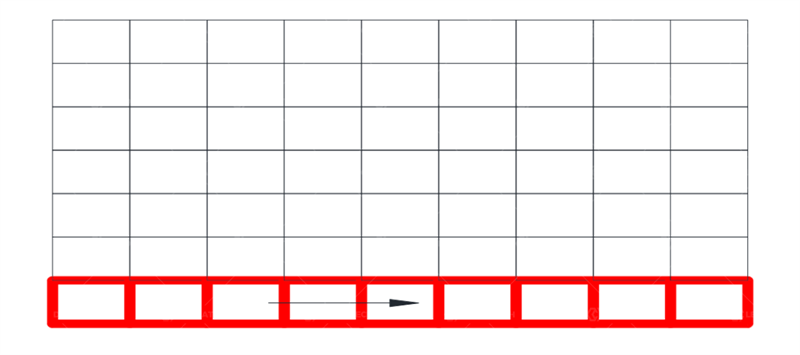

Install in sequence from bottom to top, ensuring that there is a 0.13mm gap between the two boxes (equivalent to the thickness of a piece of A4 paper).

The gap can be adjusted through the positioning pin on the top of the box.

After locking the upper and lower hooks of the box, connect the box to the steel structure bracket back strip through connecting pieces and screws (do not tighten tightly).

Then hook and lock the left and right sides of the cabinet to lock the screws of a cabinet.

After completion, measure the verticality and “⊥” line flatness. After ensuring the verticality and flatness, tighten the screws fixing the box and the back strip in place;

Indoor full-color LED Screen Installation Guide