In recent years, we often hear about COB light source, COB package or COB LED display. Many users don’t know what they mean and what is the difference between them and the commonly used LED.

Today, LEGIDATECH will introduce them to you so that you can have a general understanding.

What is COB light source?

COB light source is the abbreviation of Chip on Board, which means a light source in which the chip is directly packaged on the circuit board.

Compared with traditional SMD LED lights, COB light sources have higher brightness and more uniform light spots. Thereby improving the integration and flexibility of the light source.

At the same time, COB light sources also have lower energy consumption and higher light efficiency, making them widely used in the fields of lighting and display.

This technology eliminates the concept of brackets, no electroplating, no reflow soldering, and no patch process, so the process is reduced by nearly one-third, and the cost is also saved by one-third.

COB light source can be simply understood as a high-power integrated surface light source, and the light output area and size of the light source can be designed according to the product appearance structure.

The characteristics of COB light source products are cheap, convenient, and electrically stable, and the circuit design, optical design, and heat dissipation design are scientific and reasonable. More advantages than LED!

The advantage of COB planar light source is that the divergence of light is large and wide, and the area of light source is relatively full.

The disadvantage is that it consumes more power and is more troublesome to set up.

Features of COB light source:

1. It can be freely matched and combined to form a variety of LED lamps, which is easy to assemble. It can overcome the shortcomings of large size and high cost of SMD LED.

2. High reliability, no dead lights, no plaques. Its precision packaging process allows the chip to be fully cooled to ensure the quality of the chip and extend its life.

3. Uniform light emission, soft light, no glare, and no eye damage. It can directly overcome the shortcomings of high-power LED dazzling in the market.

4. High color rendering index and high light efficiency. It can achieve 120lm/w, and the light angle is above 120°. Save costs, no need to make another PCB board, green and environmentally friendly, no pollution.

5. Under normal current, the attenuation is minimal, controlled within 1000H less than 3%.

6. Safe and reliable, all work below 50V, and fully consider the certification of the application.

What is COB LED display?

COB display means LED display composed of COB packaging technology, which is a new LED packaging technology that uses chip-on-board packaging.

COB LED display consists of multiple LED chips and is realized through COB packaging technology.

This technology can provide higher brightness and more uniform light distribution, which is suitable for some application scenarios that require high-quality display.

COB packaging technology

COB packaging technology is also classified as a packaging-free or packaging-saving mode, but this packaging method does not save the packaging link, but saves the packaging process.

Compared with the patch process, the COB packaging process saves several steps to save time and process to a certain extent, and also saves costs to a certain extent.

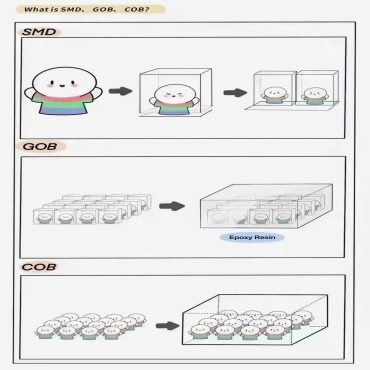

The production process of SMD requires solid crystal, wire bonding, dispensing, baking, stamping, light separation and color separation, taping, patching and other links.

The COB process is simplified on this basis. First, the IC is attached to the circuit board, then fixed, wired, tested, glued, and baked to become a finished product.

From the production process alone, several steps are omitted. Industry insiders said that this can save a large part of the cost.

One thing worth noting is that COB packaging does not require reflow soldering, which is also one of the advantages of COB.

Advantages of COB display:

1. Smaller dot pitch and more delicate picture.

The micro-pitch LED display screen with COB packaging technology avoids the SMT reflow soldering that the device needs to go through, and the pixel points do not need a special pad space.

Instead, it can achieve a smaller dot pitch, more pixels per unit area, improve the resolution of the entire screen, display more content, and make the picture clearer and more delicate.

2. The ink color is darker and the color contrast is fuller.

This type of display can present more details on the same size screen, making pictures or videos look clearer and more vivid.

For places that require high-quality display effects, this type of display will be very attractive.

P1.25: SMD LED display VS COB LED display

3. Eliminate moiré and watch more comfortably.

The COB micro-pitch LED display screen adopts a high filling factor optical design, uniform light emission, and is close to a “whole-surface light source”, which effectively eliminates moiré.

4. Low pixel loss rate.

During use, due to the COB packaging process, LED chips and other elements are completely protected in the colloid, completely eliminating the damage to pixels caused by collision, static electricity, temperature, humidity, pollution and other factors.

The COB package’s micro-pitch bad pixel rate and the whole screen out of control rate are controlled below one millionth.

5. Ultra-wide viewing angle, display at any angle.

The coating layer used in the COB package can achieve the effect of scattered light, so the viewing angle is wider, making the COB package micro-pitch LED display have a vertical and horizontal bidirectional 170° ultra-wide viewing angle.

6. Better protection performance

The COB packaged LED lamp and the PCB board are on the same plane, so when impacted by external force, it will not cause other lamp beads to fall.

Better protection performance, slight impact will not be greatly affected.

7. Good sealing and easy to clean.

COB packaging technology packages pixels on PCB boards, achieving full density of PCB circuit boards, crystal particles, solder feet and leads.

The surface is smooth without exposed components, and the surface of the pixels is smooth and hard.

It has the properties of anti-knock, anti-collision, anti-vibration, anti-pressure, waterproof, moisture-proof, dust-proof, anti-oil, anti-oxidation, and anti-static.

High stability and easy maintenance, daily cleaning and maintenance can directly wipe off surface stains with a wet cloth.

In actual use, COB modules are generally assembled and integrated through a box, and installed in the form of a box structure.

Pingback: Virtual Shooting Track: How Did LED Screens Transform from a “Luxury Item” to a “Standard Feature”? – Site Title