P3mm LED Module

P3 Indoor LED Screen Module 192mmx96mm

- Features

- p3 indoor led module Data sheet

- P3 indoor led module TECH ARTUCLES

There is basically no difference in display effect between the p3 soft module and the conventional module, whether it is brightness, contrast or refresh.

But the characteristic of the soft module is that it can be bent into different angles, whether it is an inner arc, an outer arc or a right angle. And its viewing angle is very wide, reaching 160 degrees.

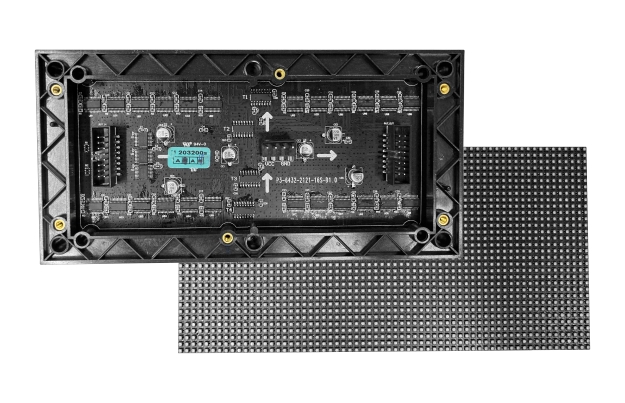

p3 indoor module-Full color lamp beads

High-quality full-color surface-mount lamp beads, stable quality, good color rendering effect and long life.

p3 indoor module-Guardrail

It is used to protect the pin header and prevent the pin header from deformation, which is more conducive to convenient installation.

It can also prevent the pin header from being squeezed and deformed during transportation.

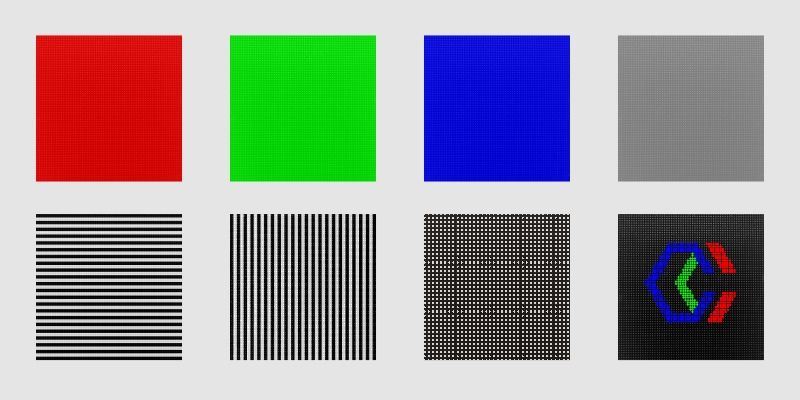

p3 indoor LED display module lighting test

After the production is completed, we will place each module on the aging rack for lighting testing.

Ensure that every lamp bead of every module is inspected, and faulty p3 led modules are repaired and replaced in a timely manner to ensure the quality of the p3 modules and prevent customers from receiving dead lamp products.

Complete accessories

pure copper wire; power adapter; power cables; rainbow wiring; screws; flat cables

vacuum plastic sealing; foam strips to protect the surrounding area

| Value | |

| Pixel Pitch | 3 |

| Module Size(mm) | 192*96 |

| Module Pixel | 64*32 |

| Brightness | 1000 |

| Pixel Configuration | SMD2121 |

| Colors | 281trillion |

| Refresh Rate (HZ) | ≥3840 |

| Pixel Matrix Per Sq.m | 43264 |

| View Angle (H/V) | 140/140 |

| Power Comsuption(max/avg) | 400/150 |

| IP Rate | IP40/20 |

| Input Voltage (AC) | 110/240 |

| Operating Temp. | -20-60 Celsius degree |

| Operating Humidity | 10-95% RH |

| Control Distance | Ethernet cable 100m, optical fiber 5km |

| Support VGA Mode | 800×600,1024×768,1280×1024,1600×1200 |

p3 Indoor LED Screen Module Manufacture &Aging Test

Our LED modules not only provide superior lighting effects, but also have excellent contrast capabilities.

The high contrast of p3 LED modules makes the image sharper and clearer, allowing viewers to better appreciate every detail in the image.

Compared to traditional lighting products,p3 LED modules have a higher contrast ratio and are able to present more realistic and vivid colors, creating a more lifelike visual experience.

Whether it’s on an p3 outdoor billboard, a mall display, or an p3 indoor video wall, our p3 LED modules provide excellent contrast performance to make your content unique and eye-catching.

By utilizing our p3 LED modules to the fullest, you can display higher-quality images, attract more attention, and enhance your brand image for greater market competitiveness.

In the aging test, we expose the p3 LED module to an environment of high temperature, high humidity, and high pressure, and run it continuously for a period of time to simulate long-term working conditions under actual use. Through this aging test, we can evaluate the stability, reliability and lifespan of the p3 LED module.

In testing, we focus on the following aspects:

1. Brightness stability: Whether the brightness of the p3 LED module remains stable without any obvious attenuation after long-term operation.

2. Color retention: Whether the color of the p3 LED module is durable and whether there will be obvious color shift.

3. Light attenuation: the degree of light attenuation of the p3 LED module and whether it meets the product performance indicators.

4. Power supply stability: Whether the p3 LED module can work stably at the set voltage and current to ensure normal operation for a long time.

Through these tests, we can determine the stability and life of the LED module, discover and correct possible problems in a timely manner, and ensure that product quality meets customer needs.

In addition to having a factory of more than one thousand square meters, LEGIDATECH also has specialized production machines and professional staff responsible for every production step.

From printing, component placement, plug-in placement, welding, lamp placement, screwing to module aging, p3 led cabinet assembly, to cabinet aging, vacuum packaging and shipment, every step is carefully inspected and processed. .

This is to ensure that the materials, processes and finished products of each product can withstand the test of customers.