Chip-on-Board (COB) and Glue-on-Board (GOB) have emerged as significant innovations, each offering unique benefits and challenges.

Understanding COB and GOB Technologies

Chip-on-Board (COB) Technology

COB technology involves mounting multiple LED chips directly onto a substrate, typically a printed circuit board (PCB).

This method eliminates the need for traditional packaging, such as the plastic or ceramic housings used in Surface-Mounted Device (SMD) LEDs.

The LED chips are bonded directly to the PCB, and a phosphor coating is applied to achieve the desired color output.

This approach not only simplifies the manufacturing process but also enhances the overall performance of the LED screen.

One notable example of COB technology in action is our Ehonor Series, which has gained significant traction among high-end clients.

The Ehonor Series leverages COB technology to deliver exceptional brightness, color accuracy, and durability, making it a preferred choice for applications where visual quality and reliability are paramount.

Glue-on-Board (GOB) Technology

GOB technology, on the other hand, involves applying a layer of transparent glue over the LED modules after they have been mounted on the PCB.

This glue acts as a protective layer, enhancing the durability and reliability of the LED display.

The glue used in GOB technology is typically a high-transparency, high-hardness material that can withstand environmental stressors, making GOB screens highly resilient in challenging environments.

Key Differences Between COB and GOB

Packaging and Assembly

COB: In COB technology, the LED chips are directly bonded to the PCB, which simplifies the packaging process.

This direct bonding reduces the thermal resistance between the LED chips and the PCB, improving heat dissipation and overall performance and enabling higher pixel density and better image quality.

GOB:GOB technology involves an additional step of applying a protective glue layer over the LED modules.

This step adds an extra layer of protection but also introduces additional material and processing steps.

While this increases manufacturing complexity, the protective benefits of the glue layer can significantly enhance the durability of the display.

Durability and Protection

COB:COB displays are known for their robustness due to the direct bonding of LED chips to the PCB.

This design minimizes the risk of damage from physical impacts, moisture, and dust. However, the lack of a protective layer can make COB screens more susceptible to environmental factors if not properly sealed.

For instance, in outdoor applications, COB displays may require additional protective measures to ensure longevity.

GOB:The glue layer in GOB technology provides an additional barrier against environmental factors such as moisture, dust, and physical impacts.

This makes GOB screens more durable and suitable for harsh environments, including outdoor applications.

The protective glue layer also helps to prevent corrosion and other forms of degradation, ensuring a longer lifespan for the display.

Heat Dissipation

COB:The direct bonding of LED chips to the PCB in COB technology enhances heat dissipation.

This is crucial for maintaining the performance and longevity of the LED screen, especially in high-brightness applications.

Efficient heat dissipation helps to prevent overheating, which can lead to color shift, reduced brightness, and even component failure.

GOB:While GOB technology also offers good heat dissipation, the additional glue layer can slightly impede heat transfer compared to COB.

However, advancements in glue materials have minimized this impact, making GOB displays still highly efficient in heat management. In many cases, the protective benefits of the glue layer outweigh the minor reduction in heat dissipation.

Optical Performance

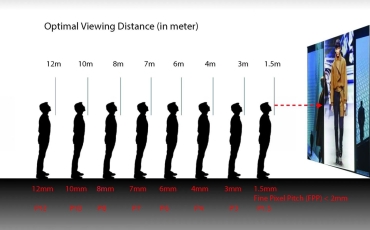

COB:COB LED screens typically offer superior optical performance due to the direct bonding of LED chips.

This results in better color consistency, higher brightness, and improved viewing angles.

The absence of traditional packaging also reduces the risk of color shift over time, ensuring that the display maintains its visual quality throughout its lifespan.

GOB:GOB displays also provide excellent optical performance, with the glue layer helping to enhance color uniformity and reduce glare.

However, the additional layer can slightly affect light transmission, potentially leading to a minor reduction in brightness compared to COB screens.

Despite this, GOB screens are still capable of delivering high-quality visuals, making them suitable for a wide range of applications.

5.Manufacturing Complexity and Cost

COB:The manufacturing process for COB displays is relatively complex due to the direct bonding of LED chips to the PCB.

This complexity can lead to higher production costs, especially for large-scale screens.

GOB:GOB technology involves an additional step of applying the glue layer, which can increase manufacturing complexity and cost.

However, the protective benefits of the glue layer can offset these costs by reducing the need for additional protective measures in the final product.

In many cases, the enhanced durability and reliability of GOB displays make them a cost-effective choice for demanding environments.

Applications of COB and GOB Screens

COB LED Displays:

Indoor Applications:COB screens are ideal for indoor environments where high brightness, color accuracy, and wide viewing angles are essential.

They are commonly used in retail stores, museums, and corporate settings. The superior optical performance of COB displays makes them particularly well-suited for applications where visual quality is paramount.

High-End Displays:Due to their superior optical performance, COB screens are often used in high-end applications such as broadcast studios, control rooms, and premium digital signage.

Our Ehonor series, with its advanced COB technology, has been widely adopted by high-end clients who demand the best in display performance and reliability.

GOB LED Screens:

Outdoor Applications:GOB displays are well-suited for outdoor environments where durability and protection against environmental factors are crucial.

They are commonly used in outdoor billboards, stadiums, and transportation hubs.

The protective glue layer ensures that GOB screens can withstand the rigors of outdoor use, including exposure to rain, dust, and temperature fluctuations.

Harsh Environments:The additional protection provided by the glue layer makes GOB displays ideal for harsh environments, including industrial settings, construction sites, and areas with high levels of dust and moisture.

Conclusion

Both COB and GOB technologies offer unique advantages in the realm of LED displays. COB technology excels in optical performance and heat dissipation, making it ideal for high-end indoor applications.

On the other hand, GOB technology provides enhanced durability and protection, making it suitable for outdoor and harsh environments.

Whether you opt for the precision of COB, as seen in our Ehonor series, or the durability of GOB, you can be confident in the quality and performance of modern LED screens.

Author:Amber