In modern lighting technology, LED lamps (light-emitting diodes) have become a widely used in various lighting and display technologies due to their energy efficiency, durability, longevity, and environmentally friendly attributes.

According to different application needs and brightness requirements, there are many types and models of LED lamps, suitable for use in different scenarios.

For example, automotive lighting, indoor and outdoor decoration, advertising display, etc.

Overall, the advantages of LED lamps make them an excellent investment for both functionality and sustainability in today’s lighting solutions.

So what is LED lamps? This article offers an insightful analysis of LED lamps, including their classification and various applications.

It aims to enhance your understanding and assist you in selecting the right LED lamps to suit your needs.

LED light bulbs, or Light Emitting Diodes, are advanced semiconductor devices that efficiently emit light through the recombination of electrons and holes.

Their technology is a game changer in the lighting industry, delivering superior performance and energy efficiency.

Compared to traditional incandescent and fluorescent bulbs, LED light bulbs offer advantages such as compact size, low energy consumption, long lifespan, quick response time, and environmentally friendly properties.

These benefits make LED light bulbs an increasingly popular choice for both residential and commercial lighting solutions.

Additionally, their versatility allows for a wide range of applications, from decorative lighting to street illumination.

Today we mainly discuss the classification of LEDs by packaging form.

Dual in Line Package lamp (DIP):

The lamp beads are produced by LED lamp bead packaging manufacturers, and then inserted into the LED PCB lamp board by LED module and LED display manufacturers.

After wave soldering, DIP semi-outdoor modules and outdoor waterproof modules are produced.

Surface Mounted Device lamp(SMD):

Three-in-one is a kind of SMD technology for LED display screens, which means that SMT lamps packaged with three different colors of RGB LED chips are encapsulated in the same colloid at a certain distance.

This type of lamp beads is widely used in TVs, LED screen, mobile phones and various electronic products.

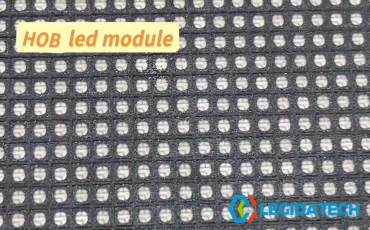

Chip on Board lamp (COB):

This type of lamp beads is a new packaging method different from DIP and SMD packaging technology.

The COB packaging process is to fix the LED bare crystal chip on the lamp pad of the PCB with conductive glue or insulating glue, then use ultrasonic welding technology to weld the conductive functional leads of the LED chip, and finally use epoxy resin glue to encapsulate the lamp position to protect the LED light-emitting chip.

It has high power and brightness, and is suitable for outdoor lighting and industrial lighting.

And here is the pros and cons of above packaging form:

DIP (Dual In-line Package) has high brightness,it is suitable for outdoor high brightness environment. And also it has good heat dissipation, the pins are directly inserted into the PCB, so the heat dissipation performance is good.

Moreover, the structure is firm and suitable for harsh environments, so it is strong stability.

But as this kind of LED is large, it is difficult to achieve high resolution.

So it is not suitable for thin and light design as well. Additionally, it requires more manual operations during soldering, which can negatively impact production efficiency and the manufacturing is complex, so the cost is very high.

For SMD (Surface Mounted Device), it has high resolution than DIP, LED is small and suitable for high-resolution display.

It will made a thin design, to suitable for indoor and thin applications.

Just like our EHONOR series, it is only 70mm, really can save a lot install space. The another advantage of this SMD is the viewing angle, it can reach more than 160 degrees.

Most importantly, SMD can doing automated production, so the cost is lower.

The disadvantage of SMD is the Low brightness, so it is not suitable for high brightness outdoor environment, it is better for indoor use.

Based on its packaging method, the heat dissipation performance and in harsh environments performance not as good as DIP.

If it is COB (Chip on Board), the LED chips are directly packaged on PCB, so it is with strong stability.

The heat dissipation performance is better than SMD. Different from SMD, COB is suitable for harsh environments, better dust-proof and waterproof effect.

If you are looking for small-pitch displays, this is a good option. But the cost of COB is higher than SMD, as the manufacturing process is complex.

We must be careful not to damage it, because it is difficult to repair a single LED damage.

Overall, DIP is suitable for outdoor high-brightness environment, but low resolution and large size.

SMD is suitable for indoor high-resolution applications, but low brightness. COB is suitable for high reliability and small pitch applications, but high cost and difficult maintenance.

The selection of packaging method should be based on specific application scenarios and requirements.