Introduction

Choosing the right LED screen power supply is as important as choosing pixel pitch. Poor power planning causes downtime, overheating, and high operating costs.

This buyer-focused article explains LED display power consumption, how to size PSUs, redundancy patterns (N+1 / UPS), safe electrical installation, and practical checks you can run with our products from the LEGIDATECH LED Screen Factory catalog (indoor P1.9, P2, P2.5).

Read on for clear answers, step-by-step examples, and an FAQ that solves the most common buyer questions.

Why LED screen power supply planning matters

A reliable LED screen power supply directly affects uptime and total cost of ownership. LED video walls list both max et typical power (W/m²).

Buyers who size infrastructure for typical use alone may be surprised during promotional reels or full-white tests, when LED display power consumption spikes.

Size PSUs for peak loads, include headroom, and plan for redundancy to avoid a single point of failure.

How to calculate LED display power consumption

Step-by-step formula (practical):

- Get vendor max W/m² et typical W/m² from the product sheet.

- Multiply max W/m² × screen area (m²) to find maximum watts.

- Apply a duty factor (content brightness) — e.g., 30–60% for mixed content, 80–100% for bright promo reels.

- Convert watts to amps (W ÷ site voltage, e.g., 230V).

- Add 20–30% margin for inrush and aging.

Example: Indoor P2.5 rated 400 W/m² max, 6 m² screen, duty 0.4 → 400 × 6 × 0.4 = 960 W → ≈4.2 A at 230 V. For PSU and breaker sizing, use the max figure and include margin (400 × 6 × 1.3 ≈ 3120 W design target).

LED screen power supply types & module voltages

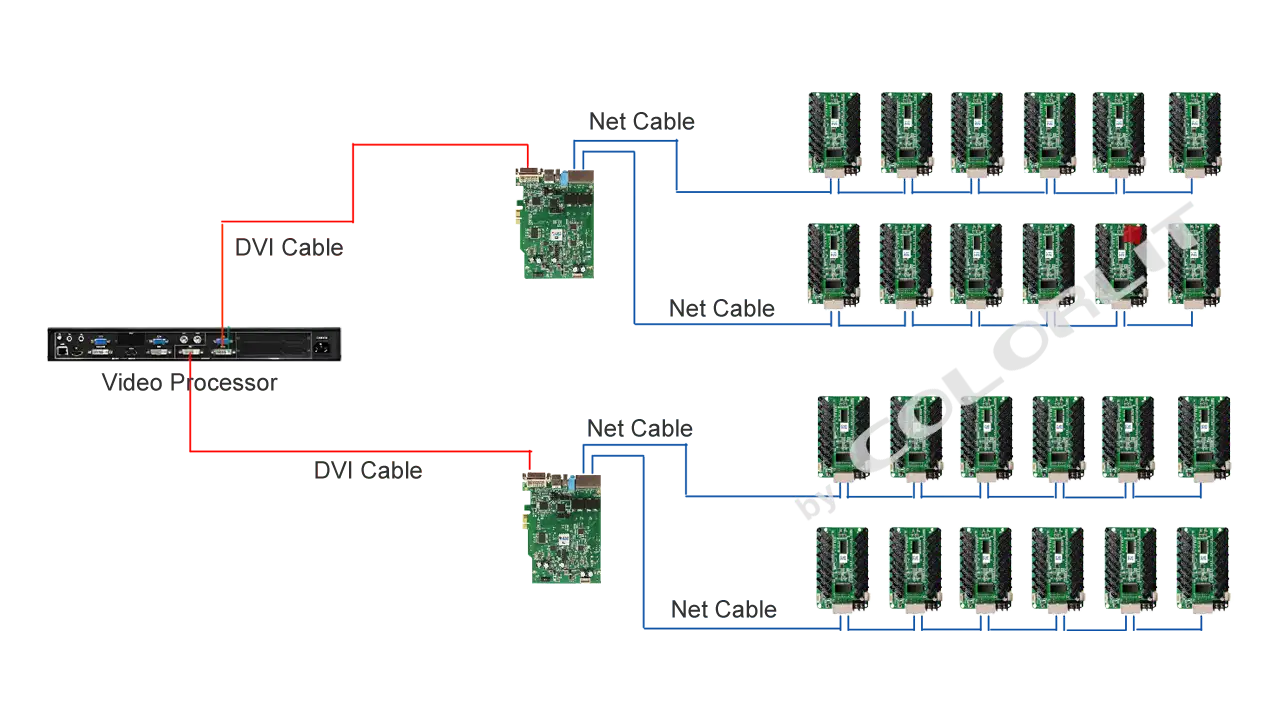

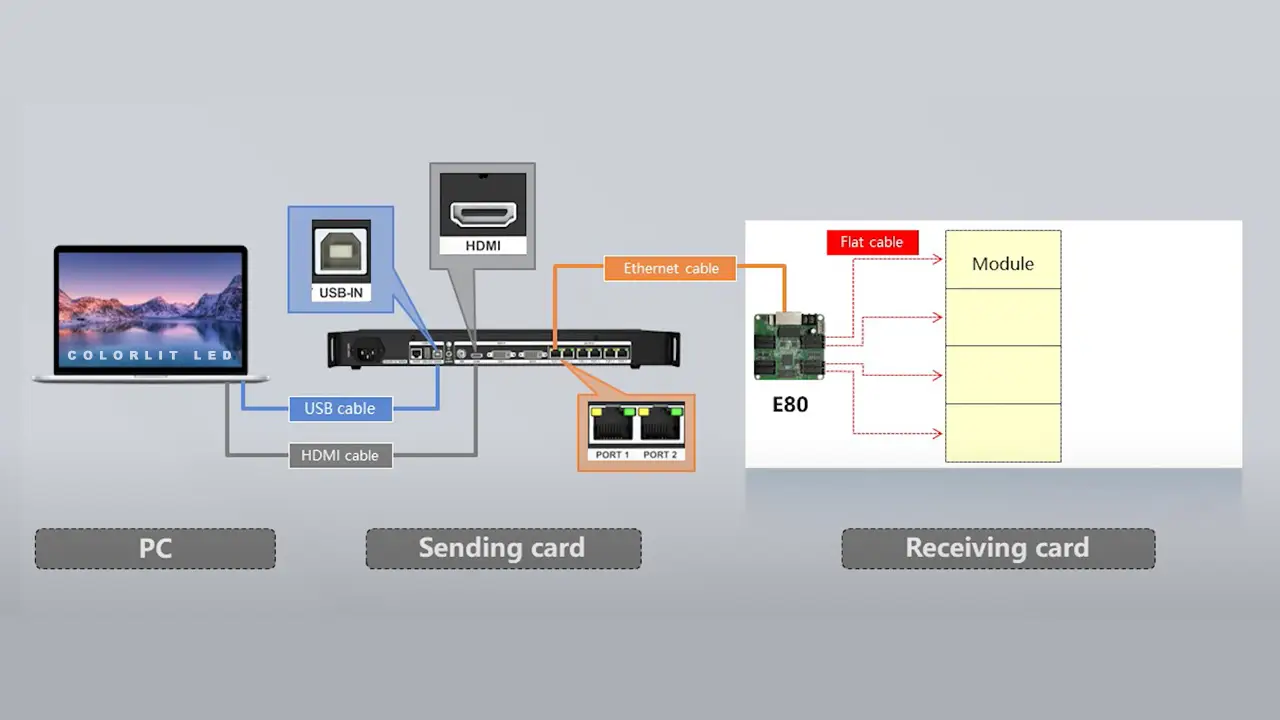

Most Murs vidéo LED use low-voltage DC rails (commonly 5V for modules) fed by multiple AC→DC PSUs distributed per cabinet.

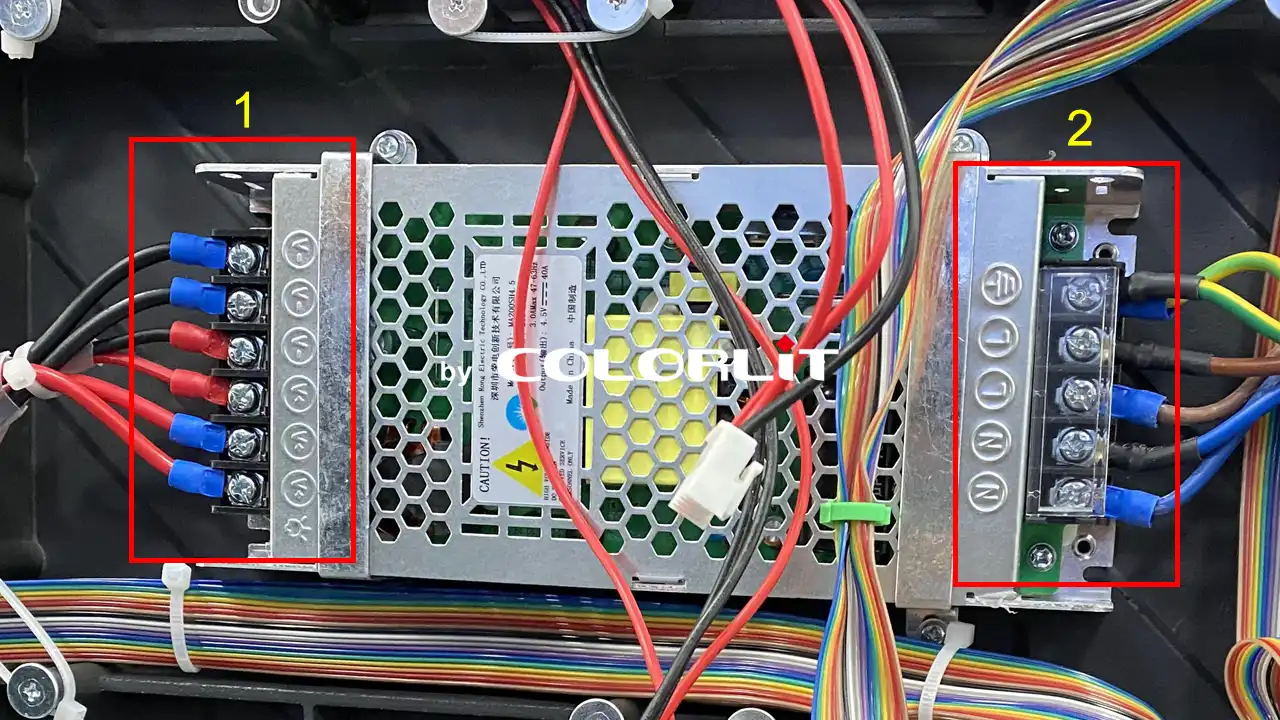

Ask vendors in the LED Screen Factory for: PSU continuous rating, efficiency, cooling method, connector type, and per-cabinet distribution diagrams.

Never wire modules directly to AC. Proper PSU topology reduces load imbalance and simplifies N+1 redundancy.

Designing redundancy & UPS for LED video wall power requirements

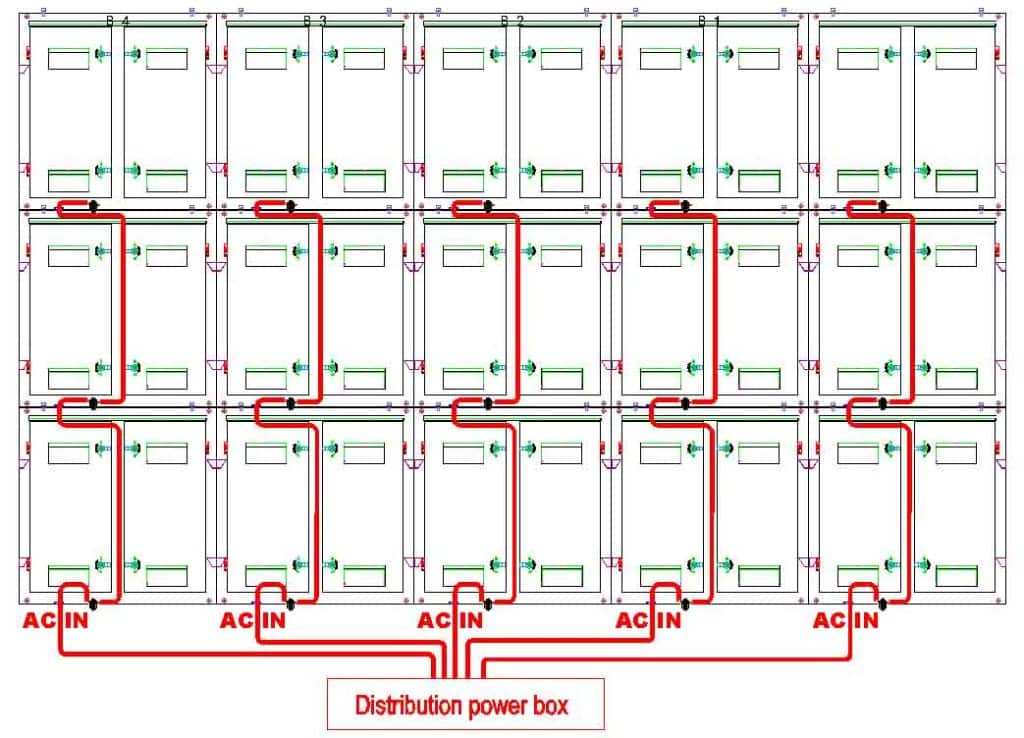

For revenue-critical streams, require N+1 PSU redundancy per cabinet and at least dual incoming AC feeds on separate breakers. Define acceptable UPS runtime (e.g., 10–30 minutes at operational load) so graceful shutdown or short continuity is possible.

Test failover during commissioning: pull a PSU or trip a breaker and verify the wall stays lit or fails over cleanly.

Buyer checklist for redundancy:

- Per-cabinet PSU maps.

- Remote PSU monitoring & health alerts.

- UPS with defined runtime and automatic transfer.

- Spare modules and hot-swap plan in SLA.

Electrical installation & safety

Buyers must insist on licensed electricians producing wiring diagrams, breaker sizing, and grounding plans. Include surge protection, correct cable gauge, derating for bundling, and ventilation plans for PSU heat. For outdoor or semi-outdoor installs, select IP-rated PSUs and rated conduits.

Operational costs: managing LED display power consumption

Power is ongoing cost. Reduce bills by: optimizing content (darker scenes, intelligent dimming), scheduling high-brightness content for short bursts, and using more efficient modules.

When comparing quotes, ask for both max et typical W/m² measured with your content. Include yearly energy estimates in your ROI model.

Acceptance testing & on-site verification

Do not accept delivery without: a full-white test, sustained burn-in at expected brightness, thermal imaging of PSUs under load, and failover tests. Require the vendor to run acceptance tests with your sample content and provide signed test reports.

Product integration — what to request from us

When you request an RFQ from LEDScreenFactory, include: target pixel pitch (P1.9 / P2 / P2.5), expected screen area, sample content for duty-factor measurement, and required UPS runtime.

We’ll provide per-tile max/typ power sheets, PSU topology diagrams, and wiring schematics. For studio installs we recommend micro-pitch P1.9 for close camera distances and P2 / P2.5 for larger sets — and we’ll size the PSUs and breakers accordingly.

Conclusion & action plan

Power planning is core to a reliable LED video wall. For every procurement: demand LED screen power supply diagrams, LED display power consumption max/typ sheets, N+1 redundancy, UPS specs, and documented acceptance tests.

Use our LED Screen Factory product pages (P1.9 / P2 / P2.5) as baseline data and request an on-site demo under your studio lights.

FAQ — Practical answers buyers ask

Q1: How much power does an LED screen use?

A: It depends on area, pixel pitch and content. Use vendor max W/m² and your content’s duty factor. Typical studio running power is often lower than max, but size infrastructure for peaks.

Q2: Can one PSU fail without taking down the whole wall?

A: Yes — with N+1 or distributed PSU topology each cabinet can survive a PSU failure if designed correctly. Require per-cabinet redundancy in SLAs.

Q3: Do I need a UPS for a studio LED wall?

A: If you depend on continuous live streams, yes. A UPS gives time for safe shutdown or keeps the wall live during short outages. Specify runtime goals in minutes.

Q4: How do I estimate energy costs per year?

A: Calculate expected average watts × hours/day × days/year and multiply by your kWh rate. Use typical W/m² figures tied to your content for realism.

Q5: What acceptance tests should I require?

A: Full-white, burn-in, thermal imaging, PSU failover and breaker trip simulation. Document results and sign off.

Author:Amy