Understanding LED Display Fundamentals

Modern LED screens consist of three core elements:

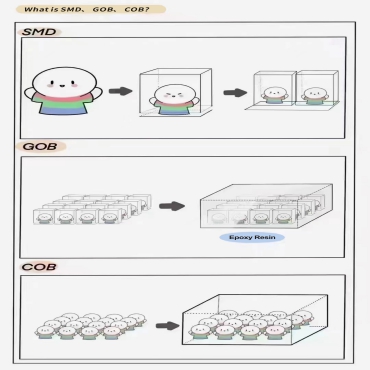

LED Modules: Clusters of red/green/blue diodes (SMD or COB packaging)

Driver ICs: Constant current regulators (typically 16-48 channels per IC)

Control System: HUB75/Ethernet-based data processing units

Thermal Runaway Risks: Core Challenges

High-power LED displays generate 500-800W/m² heat flux. At 80°C surface temperatures:

LED wavelength shifts cause 12% color inaccuracy

Driver IC efficiency drops 18-25%

Solder joint failures increase 300%

Breakthrough Solution:

256-point thermocouple array (0.1°C resolution)

PID-controlled variable-speed fans (±2% RPM accuracy)

3D Thermal Architecture Design

Vertical Thermal Pathway Optimization

Multi-layer heat transfer chain:

- Copper-clad PCB (2oz thickness)

- Ceramic-filled thermal pads (5W/mK)

- Die-cast aluminum housing (220W/mK)

- Vapor chamber assisted heat pipes

Material performance comparison:

Intelligent Airflow Management

Dynamic airflow control achieves 35% efficiency gain:

16 pressure sensors per m²

Brushless DC fans with PWM control

Auto-angled deflectors (±15° adjustment)

Case Study: Las Vegas Sphere stadium maintains 62°C component temps in 45°C desert heat.

Hybrid Cooling Breakthroughs

Phase Change Material (PCM) Integration

Technical specifications:

Latent heat capacity: 200-250kJ/kg

Custom phase transition points (45-70°C)

5,000+ thermal cycles lifespan

Saudi Arabia implementation results:

18°C peak temperature reduction

42% lower HVAC energy consumption

Atomized Cooling Synergy

Water mist system components:

50μm nozzle droplets

3D airflow acceleration tunnels

Instant vaporization heat absorption

Performance comparison:

Global Case Studies: Innovation in Action

Dubai International Airport Billboard (2023)

Challenge: Desert conditions (55°C surface temperatures) with 24/7 operational demands.

Solution: Hybrid graphene-enhanced thermal film + closed-loop liquid cooling.

Results:

32°C peak temperature reduction

28% lower energy consumption

MTBF increased to 75,000 hours

Shanghai Bund Digital Art Screen (2024)

Challenge: Coastal humidity (85% RH) combined with airborne salt corrosion.

Solution: IP69K-rated housing with anti-corrosion anodized aluminum heatsinks.

Results:

Zero corrosion failures after 2,000-hour salt spray testing

Color uniformity maintained at Δu’v'<0.005

Amazon Rainforest Eco-Monitor (2023)

Challenge: Off-grid operation in 100% humidity with biological growth risks.

Solution: Solar-powered phase change cooling + antifungal nanocoatings.

Results:

180 days autonomous operation

92% reduction in surface microbial colonization

Norway Northern Lights Observatory (2022)

Challenge: Cold starts at -45°C with display performance stability.

Solution: Self-regulating copper substrates + low-temperature lubricants.

Results:

3-minute cold start capability at -40°C

<2% brightness variance in polar conditions

Singapore Smart Traffic Network (2024)

Challenge: Monsoon rains (200mm/h) with heavy vehicle vibrations.

Solution: Hermetic vortex cooling chambers + shock-absorbing module mounts.

Results:

IP68 validation under water jet testing

IEC 60068-2-6 vibration compliance

Advanced Reliability Certification Framework

4-Stage Validation Protocol

Component Stress Testing

2,000-hour HAST (130°C/85% RH)

500-hour H2S corrosion exposure

Module Environmental Simulation

1,000 thermal shock cycles (-40°C ↔ 85°C)

10Grms sinusoidal vibration (20-2,000Hz)

System Durability Verification

IP69K hot water jet (80°C, 14MPa)

3,000-hour dust ingress testing (ISO 12103-1 A2)

Global Field Trials

12-month deployment across tropical, arid, and arctic climates

AI-Driven Predictive Maintenance 2.0

Multisensor Fusion Architecture

AI Diagnostic Engine:

CNN algorithms processing thermal image patterns

LSTM networks predicting failure timelines

Digital twin accuracy: 98.8%

Sustainable Thermal Innovations

Bio-Based Phase Change Materials

Composition: Palm oil derivatives reinforced with nanocellulose

Performance:

Latent heat capacity: 180-210 kJ/kg

68% lower carbon footprint vs petroleum PCMs

90% biodegradation within 24 months

Waste Heat Recovery System

Implementation:

- Harvest residual heat (60-80°C) from heatsinks

- Convert via Seebeck effect (8-12% efficiency)

- Feed 12-18% recovered power to display drivers

Performance Metrics:

Summary

This blog explores advanced heat dissipation solutions for LED displays operating in extreme environments.

Key components include LED modules, driver ICs, and control systems,

which face thermal risks like color shifts and solder failures at high temperatures.

Innovative solutions such as 3D thermal architecture, PID-controlled fans, PCM integration (reducing peak temps by 18°C),

and atomized cooling are highlighted.

Global case studies demonstrate success in harsh conditions: Dubai’s hybrid cooling achieved 32°C reduction,

while Singapore’s vortex chambers ensured IP68 compliance.

AI-driven predictive maintenance (98.8% digital twin accuracy) and sustainable innovations like bio-based PCMs further enhance reliability.

Annual maintenance and modular retrofits ensure cost-effective, long-term performance.

Q&A: Addressing Common Concerns

Q1: How does extreme heat affect LED display lifespan?

A: Continuous 85°C operation reduces lifespan by 55-70%. Our hybrid cooling maintains components below 65°C, achieving 80,000+ hours MTBF.

Q2: What maintenance do cooling systems require?

A: Annual inspection of:

Fan bearing wear (<0.1mm play)

Heat pipe capillary integrity

PCM recharge status

Q3: Can existing LED screens be retrofitted?

A: Yes. Modular upgrade kits enable:

25-40% thermal performance improvement

3-5 year ROI through energy savings

Q4: How to balance cooling efficiency and weatherproofing?

A: Our IP68-certified system uses:

Hydrophobic membrane filters

Pressurized airflow chambers

Corrosion-resistant aluminum alloy

Q5: How to prevent condensation in cooling systems

A: Dynamic dew point control:

Real-time humidity sensing (±2%RH)

Intelligent PTC dehumidification (<50W/m²)

Hydrophobic nano-coating (contact angle>150°)

Q6: Thermal challenges in multi-screen cascading?

A: Cascaded thermal management solutions:

Master-slave temperature coordination (CAN bus)

Edge screen enhanced cooling (+15% airflow)

Thermal expansion compensation (0.1mm/m tolerance)

Q7: Special requirements for elevated installations?

A: High-altitude cooling kit features:

Wind-resistant structure (60m/s rated)

Lightweight design (40% reduction)

Remote hydraulic maintenance ports

Q8: Handling cooling failures during power outages?

Supercapacitor backup (15min cooling)

Mechanical dampers (gravity-actuated)

Thermal fuse barriers (auto-isolate @125°C)

Author:Amy